Partner for large and small batches in high-voltage cable production

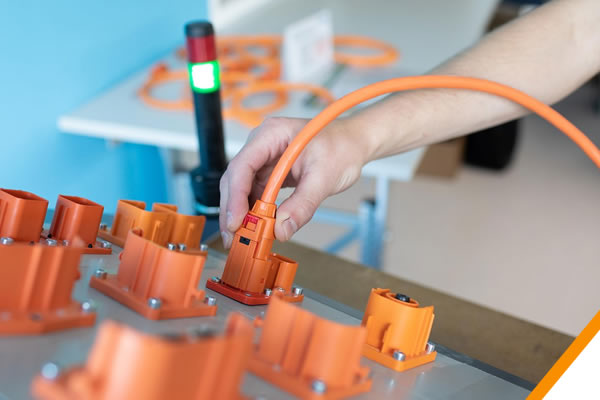

We assemble high-voltage connectors and high-voltage cables according to the VDA standard, which safely transmit the corresponding currents and control the applied voltages.

The production of prototypes in small quantities up to 50 pieces is just as much a part of our day-to-day business as series production in large numbers. We therefore rely on the low volume high mix. In cooperation with the customer, we develop individual solutions if no samples are available yet. Components from well-known manufacturers such as Amphenol or Hirschmann are used for high-voltage cable assembly. Finally, the high-voltage assemblies are checked using a fully automatic high-voltage tester (quality assurance of the HV components).

Assemble HV cables

Combine high-voltage connector systems and high-voltage cables from different manufacturers according to your needs. Whether as a “pigtail” or a pre-assembled cable set.

Our services - your advantages

We assemble cables for the on-board network of various commercial and transport vehicles. Our clients benefit from expert advice and the complete design of the high-voltage cabling. We also take on the serial production of cabling systems for rough areas of application.

- Production according to VDA guidelines, tests according to LV 123

- Sample deliveries in a short time

- Fast reaction times

- Processing of cables from the brands Huber + Suhner, Coroplast, LEONI or other brands according to your specifications up to cross-sections of 120 mm² and a temperature resistance of up to 180°C

- Processing of HV-connectors with IP67 / IP6k9k, for a temperature range from -40° C up to 140° C and for currents up to 750 A / 1,000 V in different embodiments

- Documentation plans of the cabling concept for follow-up orders

- Material procurement and stockpiling

Our equipment for certified quality

We work on two press systems: hydraulic presses (HV crimp press), with a capacity of up to 15 tons and an eccentric press with 20 tons press force. This equipment also allows crimping with corresponding crimping dies from 120 to 400 square millimetres, for predominantly unshielded cables. The tool geometry ranges from hexagonal to semi-circular with a dimple to WM shape.

Pigtail or complete system

The high-voltage modules can be designed as a so-called pigtail variant attached on one side or as a finished, double-sided version - also with different connector systems. Pigtails are partial assemblies. We also take care of the complete cabling and the production of individual components such as Power Distribution Units. Versions with pilot contacts (High Voltage Interlock) can be equipped with customer-specific lines and terminals in the inliner as well as on the header.

Quality assurance of the HV components

Before delivery, the high-voltage assemblies are tested using a fully automatic high-voltage tester with 2650 VAC / 3750 VDC.

The production of safe high-voltage cabling concepts is a challenge that requires a high degree of experience. Individual connectors and cable requirements are also defined in the delivery specifications of the German car manufacturers LV214, LV215 and LV216. The US-Car 2 and US-Car 37 specify the requirements for the North American market.